Accredited calibration services play a crucial role in maintaining accuracy and reliability across various industries, ensuring that instruments and equipment meet stringent standards. As technology advances and industry demands evolve, several future trends are set to significantly impact these services. One of the most prominent shifts involves the integration of digital technologies such as artificial intelligence (AI) and machine learning. These technologies enable more precise data analysis, predictive maintenance, and automated reporting processes within calibration activities. By leveraging AI algorithms, calibration providers can identify patterns or deviations early on, improving overall measurement quality while reducing downtime.

Another important trend is the increasing adoption of Industry 4.0 principles, which emphasize connectivity between devices through the Internet of Things (IoT). Smart sensors embedded with IoT capabilities allow real-time monitoring of instrument performance remotely. This continuous data stream facilitates proactive calibration scheduling rather than relying solely on fixed intervals or reactive maintenance after failure detection. Consequently, this shift enhances operational efficiency by minimizing disruptions caused by unplanned recalibrations.

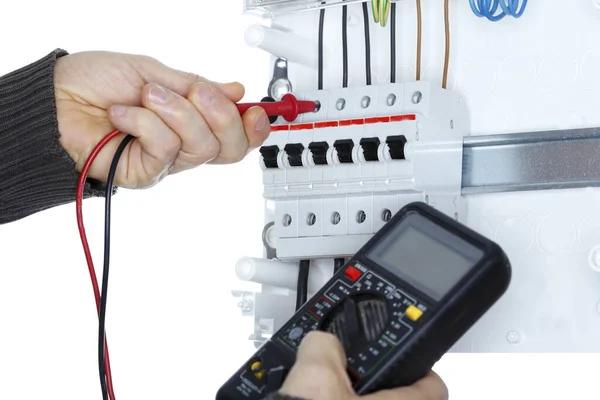

The growing complexity of manufacturing processes also drives demand for highly specialized calibration services tailored to specific industry needs like aerospace, pharmaceuticals, or automotive sectors. These fields often require compliance with rigorous regulatory frameworks where traceability and documentation get more insights are paramount. Calibration laboratories must therefore invest in advanced equipment capable of handling diverse measurement parameters while adhering to international standards such as ISO/IEC 17025 accreditation requirements.

Sustainability concerns influence future directions as well; companies increasingly seek environmentally responsible practices throughout their supply chains including metrology services. Calibration providers may adopt greener methodologies by optimizing energy consumption during testing procedures or utilizing eco-friendly materials for instrumentation components without compromising accuracy.

Cybersecurity emerges as a critical consideration due to the digitization and network interconnectivity inherent in modern calibration systems. Protecting sensitive measurement data from unauthorized access ensures integrity and confidentiality vital for maintaining trust among clients who rely on certified results for quality assurance purposes.

Furthermore, remote calibration capabilities facilitated by augmented reality (AR) tools could revolutionize service delivery models by enabling experts to guide onsite technicians virtually during complex adjustments or troubleshooting tasks without physical presence at client locations.

In summary, accredited calibration services will be shaped profoundly by technological advancements including AI-driven analytics and IoT-enabled monitoring alongside sector-specific specialization requirements driven by regulatory compliance pressures. Sustainability initiatives coupled with heightened cybersecurity measures will further define how these essential services evolve moving forward into an increasingly connected industrial landscape where precision remains paramount yet efficiency gains become indispensable for competitive advantage.